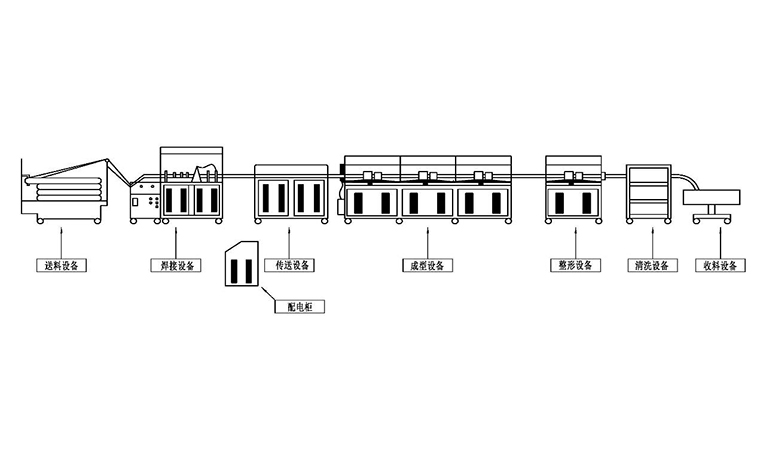

Annular corrugated hose production line is a intelligent automatic production line which could weld, form and clean to translate the raw material to hose. The equipment has the characteristics of strong stability and high efficiency. It is in an absolute leading position in the similar production line.

Parameter

| Parameter | ||

| standard | DN6-DN25 | DN32-DN50 |

| Control method | PLC | PLC |

| power | 12.1KW | 16.3KW |

| Total amount | 3100KG | 3215KG |

| Total length | 14meters | 16meters |

Feature

Stability

The production line adopts the German advanced welding technology to ensure the continuous stability of welding. The technology of delivering the raw material can make the product smoothly into the forming process.Multichannel molding technology guarantee the even wave of corrugated hose, avoiding the problem "high and low wave", which improve greatly the flexibility of the hose, fatigue resistance and life.

- To break through the limitation of the length

- Efficient production capacity

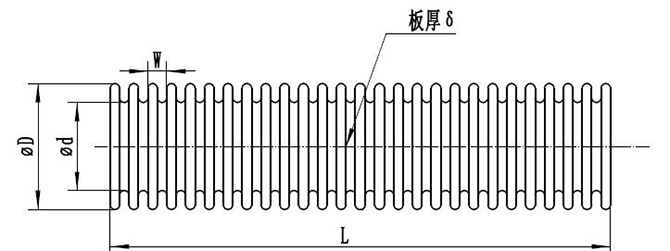

Parameter

| Parameter | |||||

| Number |

Caliber DN |

Inner diameter d/mm |

Outer diameter D/mm |

Wave distance W/mm |

Thickness δ/mm |

| 1 | 6 | 6±0.25 | 9.6±0.25 | 2±0.25 | 0.15-0.2 |

| 2 | 8 | 8±0.25 | 12.2±0.25 | 2.4±0.25 | 0.15-0.2 |

| 3 | 10 | 10±0.25 | 14.2±0.25 | 2.6±0.25 | 0.15-0.25 |

| 4 | 12 | 12±0.25 | 16.8±0.25 | 3.2±0.25 | 0.15-0.25 |

| 5 | 16 | 16±0.25 | 21.8±0.25 | 3.6±0.25 | 0.18-0.3 |

| 6 | 20 | 20±0.25 | 26.6±0.25 | 3.8±0.25 | 0.18-0.3 |

| 7 | 25 | 25±0.3 | 32.3±0.3 | 3.8±0.3 | 0.20-0.35 |

| 8 | 32 | 34±0.3 | 41.1±0.3 | 3.8±0.3 | 0.22-0.4 |

| 9 | 40 | 40±0.3 | 49.5±0.3 | 5.3±0.3 | 0.25-0.4 |

| 10 | 50 | 50±0.5 | 60.5±0.5 | 5.3±0.5 | 0.25-0.4 |

sales04@cnwide.com.cn

sales04@cnwide.com.cn sales04@cnwide.com.cn

sales04@cnwide.com.cn